Steam is the pulsing artery of industrial processes, driving activities at power plants, refineries, and manufacturing facilities. The efficiency, safety, and performance of such operations depend on their control of steam temperature.

It is here that desuperheaters come into play: they help decrease superheated steam to a specific temperature for equipment protection, improvement of process efficiency, and high-quality product achievement.

Let’s discuss why desuperheaters are a must in controlling steam temperature and how they affect several industries.

What Are Desuperheaters?

A desuperheater is a cooler for superheated steam specifically, bringing its temperature to a point just above the saturation of the steam. A lot of energy can be transferred by superheated steam, as it is highly efficient.

It causes parts to wear and tear down and is not used for certain industrial processes. Desuperheaters inject a fine spray of water or employ sophisticated mechanical systems to bring steam up to a required temperature and ensure steam meets a certain operational requirement.

In any industry that requires precise steam control, like power generation, food processing, petrochemicals, or pharmaceuticals, these devices play a crucial role. Their capacity to control temperature makes them the cornerstone of modern steam systems.

Why Steam Temperature Control Matters

Steam temperature control is not just a technical necessity but an operational necessity as well, because without proper temperature management, systems easily degrade into inefficiency, damage, and even safety hazards. Here are the major reasons why steam temperature control is important:

- Reducing Equipment Damage: Superheated steam can degenerate and even destroy delicate pieces of equipment over time. Temperature control will prevent costly fixes as well as lost time due to downtime.

- Enhancing Efficiency: Steam at optimal temperatures ensures maximum energy transfer, reducing wastage and operational costs.

- Ensuring Safety: Overheated steam can lead to dangerous pressure imbalances and accidents. Controlled steam temperatures minimize these risks.

- Meeting Process Requirements: Many industrial processes require steam at precise temperatures for consistent quality and performance.

Desuperheaters are the solution to achieving these goals, providing the accuracy and reliability necessary for steam systems.

How Desuperheaters Work

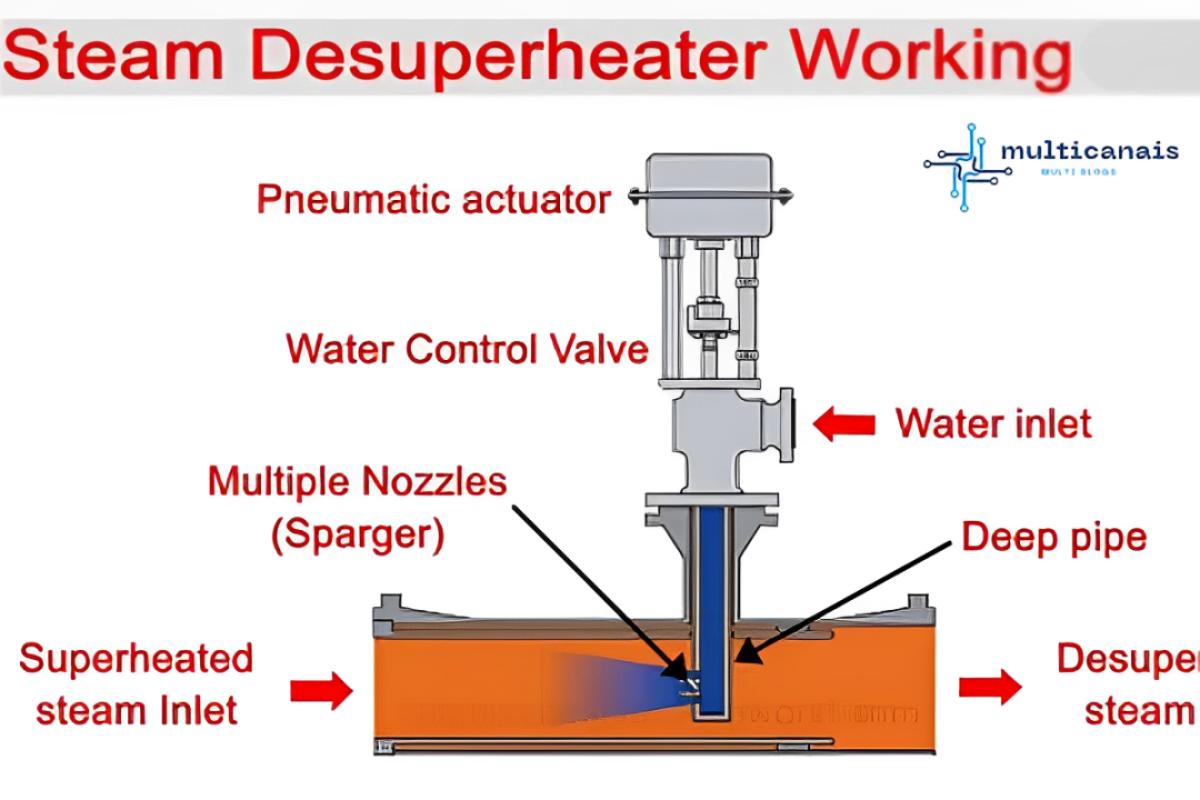

A superheater works by introducing a cooling medium, which is normally water, into the steam flow. The remaining heat is absorbed by the cooling medium, thus cooling it down without condensing it to water droplets. Advanced designs ensure uniform cooling with minimal pressure drop, hence suitable for high-performance applications.

There are a few options available for desuperheaters, including spray-type, venturi-style, and mechanical options. These all have specific features but are unique to specific industrial needs, where they share the same goal: precise steam temperature control.

Benefits of Using Desuperheaters

The various benefits of using desuperheaters go beyond just temperature regulation. They ensure efficiency, cost savings, and reliability in the entire system. Here’s why desuperheaters are a must-have for industrial steam systems:

- energy efficiency: By optimizing steam temperature, superheater desuperheaters avoid energy losses, so running the system at peak performance.

- Cost Savings: Controlled temperature reduces the wear and tear of machinery and thus saves on maintenance costs and increases the life of machinery.

- Operational Flexibility: Desuperheaters enable systems to accommodate fluctuating process conditions, thus enabling the use of steam for specific needs.

- Environmental Impact: Increased efficiency means reduced fuel consumption and lower emissions that meet the principles of sustainability.

- Accuracy and Reliability: Desuper heaters ensure precise temperature modulation, ensuring consistent performance for operations.

Industrial Users of Desuperheaters

Desuperheaters are needed in all types of industries that rely on steam in their processes. An industry needs the control of steam temperature for safety, efficiency, and quality. Here is a more detailed description of the types of industries:

- Power Generation: The steam turbines function at specific conditions of temperature to optimize efficiency and provide extended lifespan. Desuperheaters help to prevent steam from overheating and maintain optimal power generation conditions.

- Petrochemical refineries: In the refining process, superheated steam is used that must be controlled precisely for safe and efficient process execution.

- Food Processing: The steam industry relies majorly on cooking, sterilization, and drying, and desuperheaters must provide steam at appropriate temperatures to serve hygienic and process-specific purposes.

- Pharmaceutical: In pharmaceutical industries, steam sterilization demands precise temperatures to ensure the safety and efficacy of their product.

- Pulp and Paper: In processes like drying and bleaching, superheaters are critical since steam temperature is potentially dangerous to the final product.

Problems in Cases without Desuperheater

Steam systems are very tough to operate without superheaters. Overheated steam will make the machinery wear out faster, consume more energy, and give uneven quality to the product.

More importantly, the equipment will most probably fail, and safety risks are also higher. All of these issues are effectively answered by including desuperheaters in the system, allowing for smooth operations with minimal problems.

Conclusion

Desuperheaters are those steam system heroes that provide precise temperature control to improve efficiency, protect equipment, and even just generally improve the operation of the system. This makes their role important in most industries, from power generation to pharmaceuticals.

Investing in desuperheaters means more than just fine-tuning steam temperature control. It contributes to making processes safer, more efficient, and economical. Knowing why desuperheaters are critical to steam temperature control can help businesses take preventive measures to optimize their operations and stay competitive.

Given the continuously increasing demands for precision and efficiency, desuper heaters are no longer luxuries but necessities for industrial success.

More Read: How K Energy is Powering the Next Tech Revolution

2 thoughts on “Why Desuperheaters Are Vital for Steam Temperature Control”